Bugatti Tourbillon Instrument Cluster Blends Watchmaking Art

Many modern hypercars speak to their drivers through pixels and screens. The Bugatti Tourbillon takes a different approach. Its analog instrument cluster delivers a technical and artistic achievement that unites watchmaking precision with top-tier automotive engineering. The latest episode of Bugatti’s ‘A New Era’ documentary series reveals the remarkable detail behind this mechanical instrument cluster.

The name Tourbillon reflects Bugatti’s pursuit of mechanical timelessness. Unlike earlier models that honoured legendary racing drivers, this hypercar takes its name from a watchmaking invention created in 1801. The tourbillon counters gravity’s effects to support precise timekeeping. More than 200 years later, people still treat it as the pinnacle of fine watchmaking.

This ethos demanded timeless components that would never date. Concepto, a Swiss manufacture specialising in haute horlogerie, built the solution by hand. The fully analog instrument cluster uses more than 650 individual components. Craftspeople made and finished each part with traditional watchmaking techniques and the same care you see in the world’s finest timepieces. The cluster becomes a masterpiece within a masterpiece.

"Because this car is different from its predecessors, which were named after Bugatti pilotes, this one is called Tourbillon. The idea behind this car is to have the very best in its field for every component. The engine is developed at the highest level by true specialists, and the instrument cluster is created in the same way, in collaboration with renowned experts in fine watchmaking.” Alexandra Tavares, Interior Designer and Individualization Expert at Bugatti Rimac.

For Concepto, the Tourbillon project brought both honour and a formidable challenge. The team created a bridge between the automotive world and the watch industry. They pushed for innovation while respecting both traditions. The ambition stayed clear from the start.

“We wanted to create something truly exceptional, at the level Bugatti demands. People often say, ‘If it’s comparable, it is no longer Bugatti.’ I like that phrase, because Concepto movements are much the same.” Valérien Jaquet, CEO and Founder of Concepto.

“We knew from the outset that it would be a challenge. But these are exactly the kinds of projects that are incredibly motivating for our development and design teams, and for everyone involved, because the final result is truly spectacular.”Guillaume Tripet, Project Manager at Concepto.

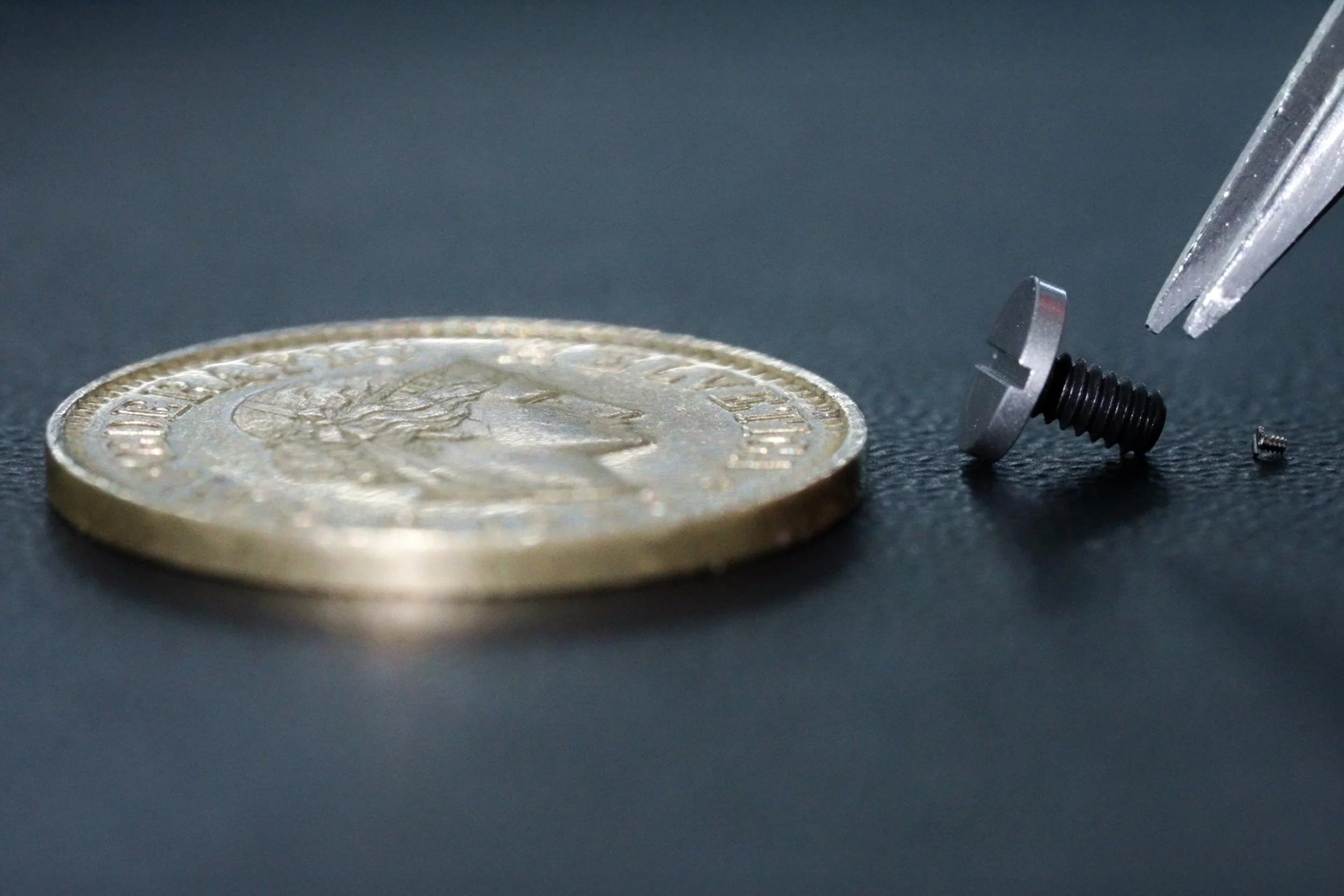

The technical demands pushed hard. The instrument cluster had to blend the mechanical precision of haute horlogerie with automotive electronics that could match the Tourbillon’s performance. These components sit far outside traditional watchmaking, yet the team integrated them cleanly with hand-finished mechanical elements. The scale gap added another hurdle. Watch parts often measure in millimetres, but the Tourbillon’s cluster modules operate on a far larger scale. Even so, the team kept the same obsessive attention to detail and uncompromising finishing standards. Standard watchmaking tools did not fit the task, so Concepto developed new methods and equipment for this instrument cluster.

"The concept of creating something that transcends time fits perfectly within the world of fine watchmaking. As a watchmaker, building the instrument clusters for Bugatti is an amazing project. We're applying centuries-old traditions to create something that will remain relevant and beautiful for generations to come, which is exactly what we strive for in haute horlogerie."David Olafsson, Watchmaker at Concepto.

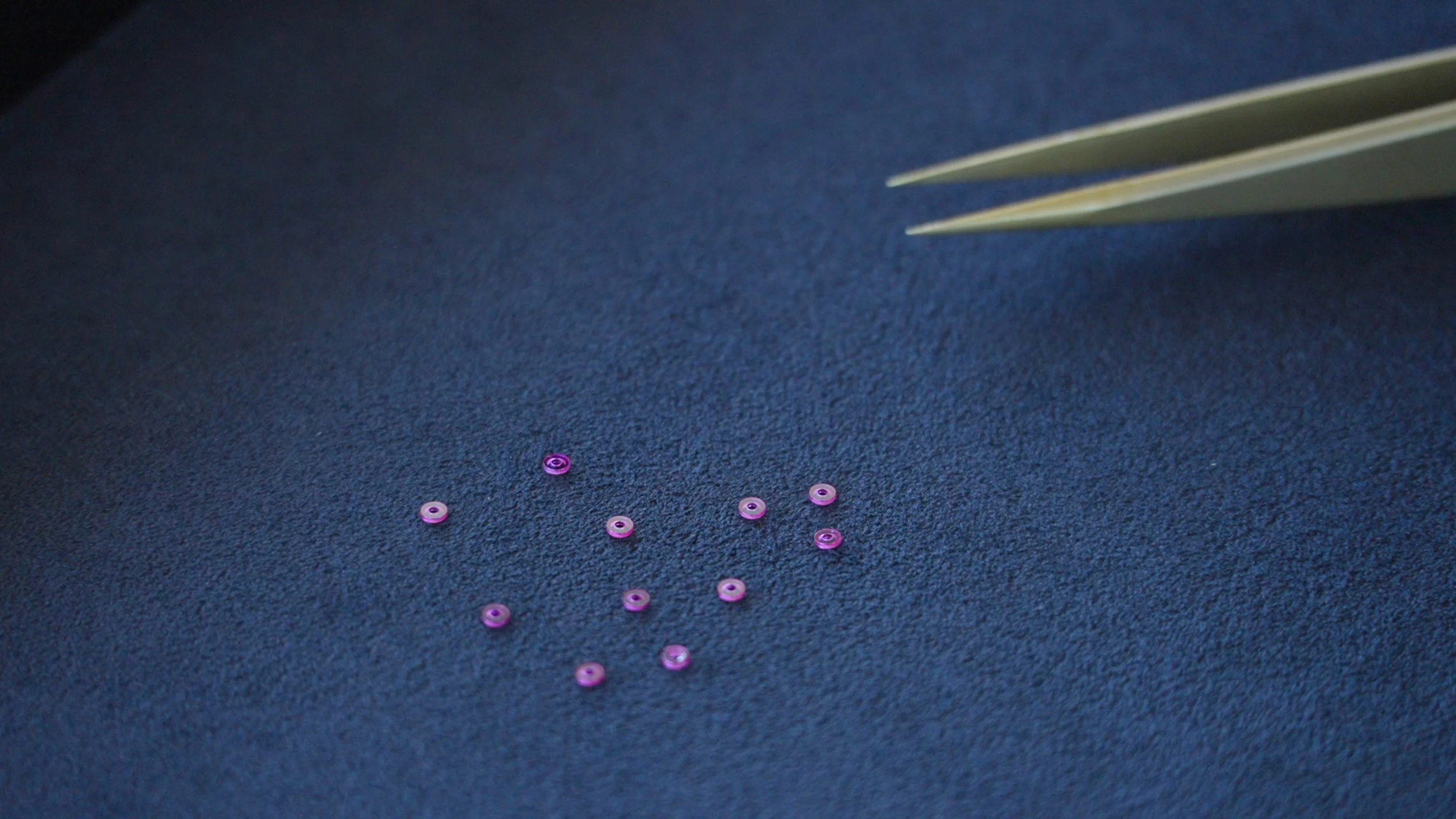

The Tourbillon instrument cluster displays finishing techniques that watchmakers usually reserve for the finest timepieces. Customers can choose decorative finishes such as Clous de Paris, radial guilloché, tapestry, and engine-turned patterns that echo Bugatti’s historic design language. They can also choose highly exclusive gemstone options such as Aventurine. Bugatti presents each finish as a physical sample, so customers can judge the look in person rather than relying on digital renderings. Functional rubies act as bearing jewels. They do not serve as a visual flourish, because ruby offers the best material to reduce friction in the mechanical movements. Sapphire crystal, skeletonised structures, and hand-finished needles ensure every visible component meets the exacting standards of Bugatti and Concepto. Designers created the gears specifically for the Tourbillon, so they stay unique to the car and the brand.

The team also had to integrate automotive technology. They incorporated LEDs and PCBs into an assembly process that usually avoids such parts. Material choices shifted throughout development. Lighter materials introduced fresh limits on colour and finish options, and the team also accounted for diamond-encrusted elements.

“You could think of it as a car within a car, because it has its own – let’s say – heart. Like a watch, you have the engine and all the mechanisms, and you create your own piece, your own design. Here, it’s the same: the cluster is a piece in its own right within the car, yet it belongs to the car as a whole. With more than 650 components, there are countless ways to customize it, making it a masterpiece within the masterpiece that is the Tourbillon.” Alexandra Tavares, Interior Designer and Individualization Expert at Bugatti Rimac.

The cluster stands out even more because the Tourbillon uses a fixed-hub steering wheel design. This layout keeps the instrument panel unobstructed, whatever the steering input. The wheel rim rotates around the cluster, so spokes never block the driver’s view. This decision puts the analog instrument cluster at the centre of the driving experience and keeps craftsmanship in view at all times.

By combining automotive engineering with traditional watchmaking, the Tourbillon instrument cluster expands personalisation options. The 650-component assembly lets clients specify finishes, materials, and details in ways that conventional dashboards cannot match. The result brings haute horlogerie precision to the demands of a modern hypercar. It also gives clients the ability to configure a functional work of craft to their own specification, much like commissioning a bespoke timepiece.

“Timelessness is one of the core pillars of Bugatti. We create automobiles that are meant to be admired not only today, but on the lawns of Concours even 100 years from now. That commitment to longevity demands absolute perfection and craftsmanship in every detail. When the idea of an entirely analog instrument cluster emerged, it was clear that we needed a partner who shared this uncompromising philosophy. In Concepto, we found exactly that – a team capable of bringing this bold vision to life at the highest level. Seeing our customers now explore the countless possibilities to design their own clusters during configuration sessions is incredibly inspiring, and we look forward to witnessing these highly personal masterpieces come to life.” Hendrik Malinowski, Managing Director of Bugatti.