Ferrari Elettrica: First All-Electric Supercar Revealed

Ferrari will reveal the production-ready chassis and components of its first fully electric car at Capital Markets Day 2025, marking a milestone in the Prancing Horse’s multi-energy strategy spanning internal combustion, HEV, PHEV and now pure electric drive. The new Ferrari Elettrica blends state-of-the-art technology with superlative performance and the driving pleasure that defines every Ferrari. Engineers in Maranello developed and manufacture the main components in-house to guarantee the uniqueness and performance only Ferrari can offer in an electric supercar.

This model crowns a journey that began with hybrid tech derived from the 2009 Formula 1 car. Ferrari progressed from the 2010 599 HY-KERS prototype to the 2013 LaFerrari, then to the SF90 Stradale —the marque’s first plug-in hybrid —and the 296 GTB, and the recently presented 849 Testarossa. This experience provided the expertise needed to create an electric Ferrari that excels in every dimension.

From the outset, Ferrari set a clear rule for its first electric model. It would arrive only when available technology could ensure authentic Ferrari performance and driving feel. The project now moves into production, featuring more than 60 patented, proprietary solutions. Ferrari manufactures both chassis and bodyshell with 75% recycled aluminium, cutting 6.7 tonnes of CO₂ per vehicle built and advancing sustainable supercar engineering.

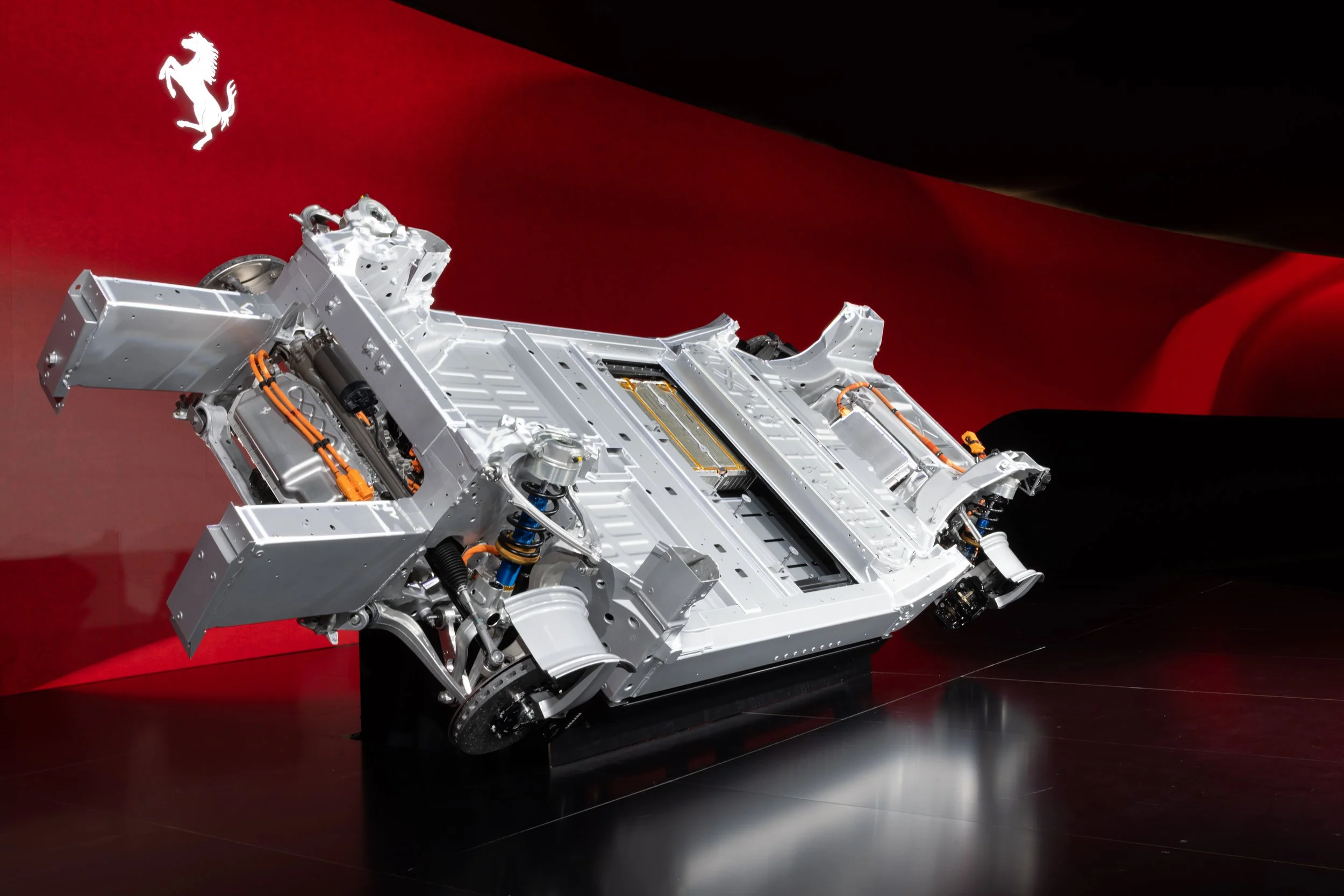

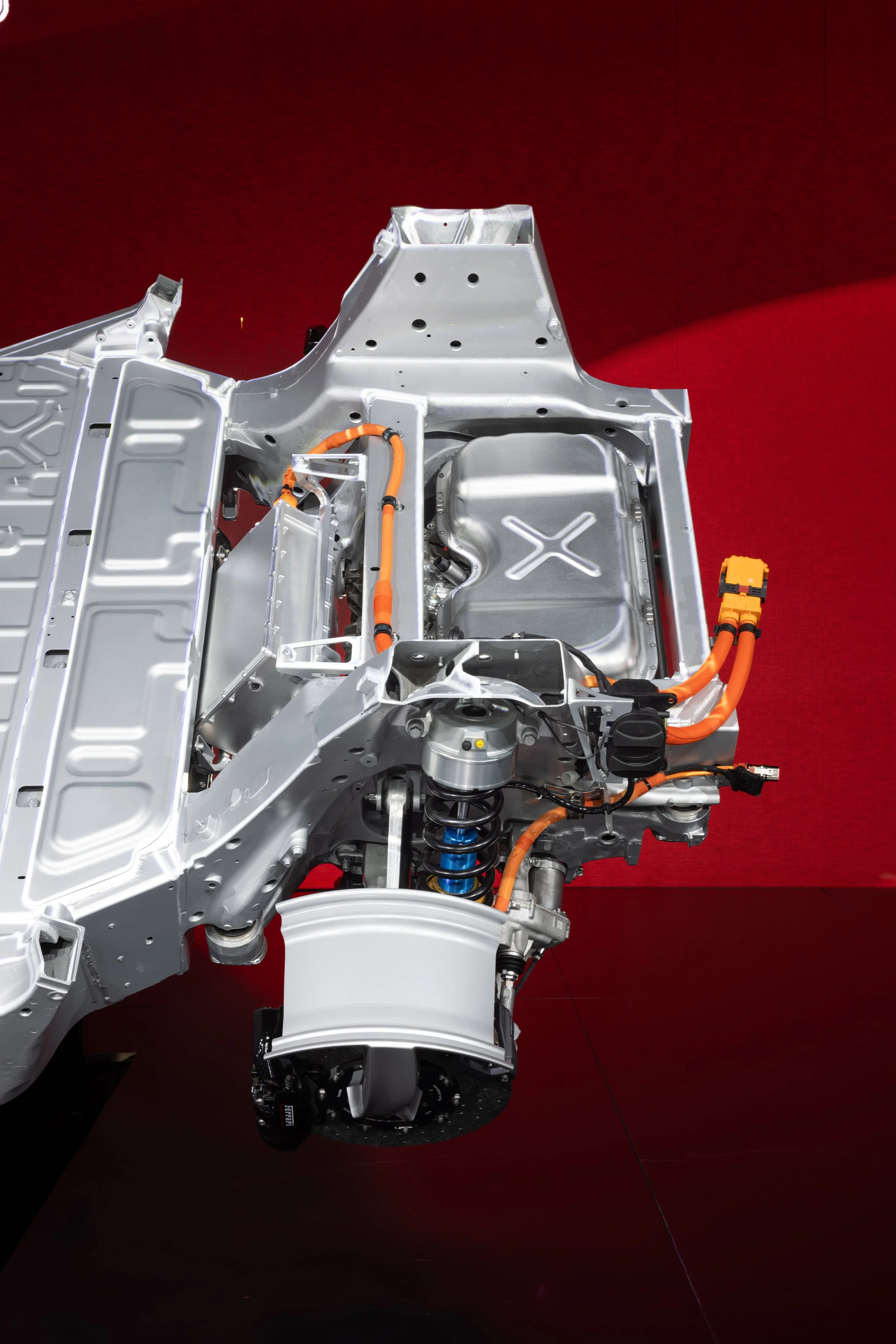

The architecture features short overhangs, an advanced driving position positioned close to the front axle, and a battery integrated into the floorpan. Engineers placed the modules between the axles, with 85% of the mass as low as possible to drop the centre of gravity. The Elettrica sits 80 mm lower in centre of gravity than an equivalent ICE model, which sharpens responses and benefits handling in an EV context.

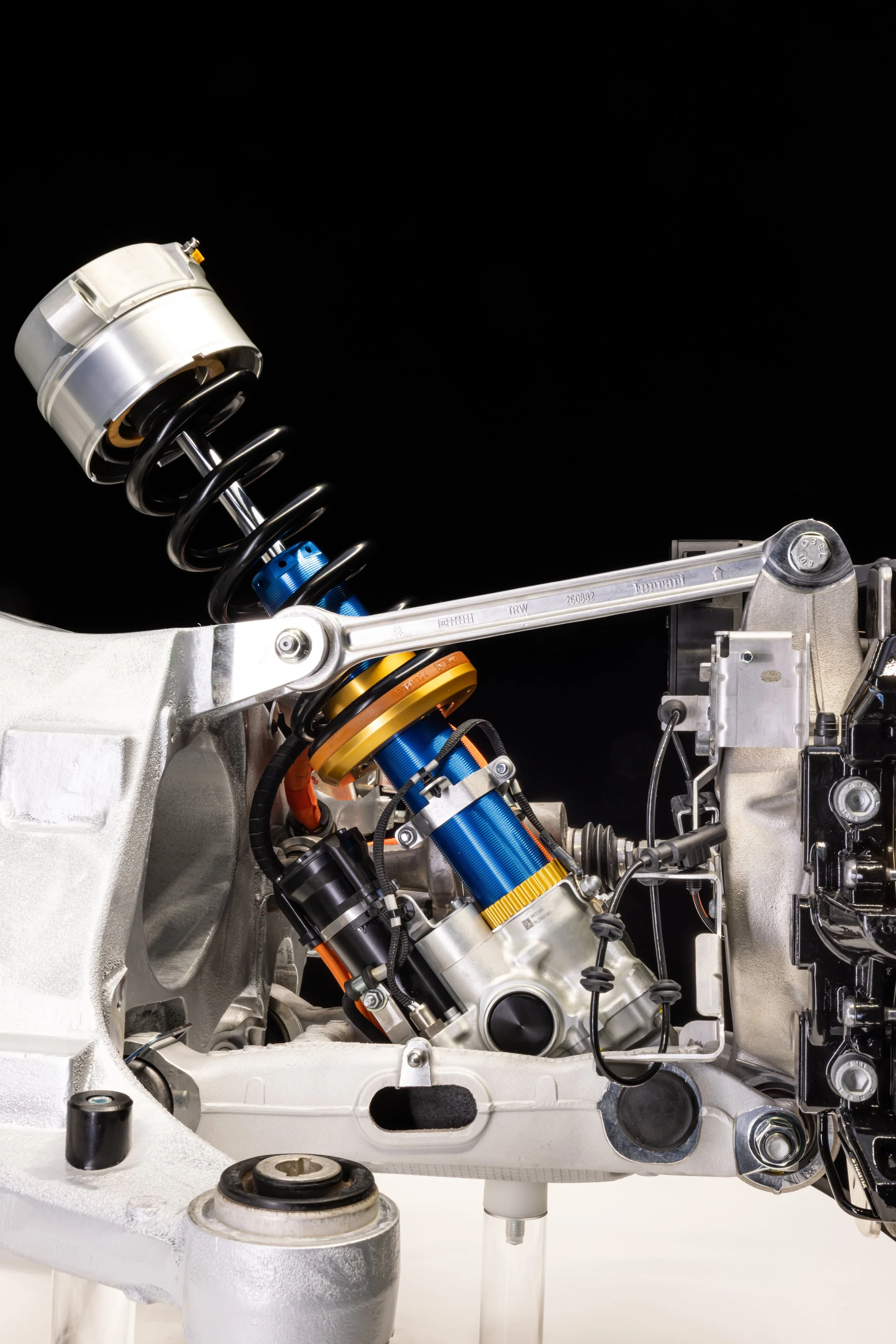

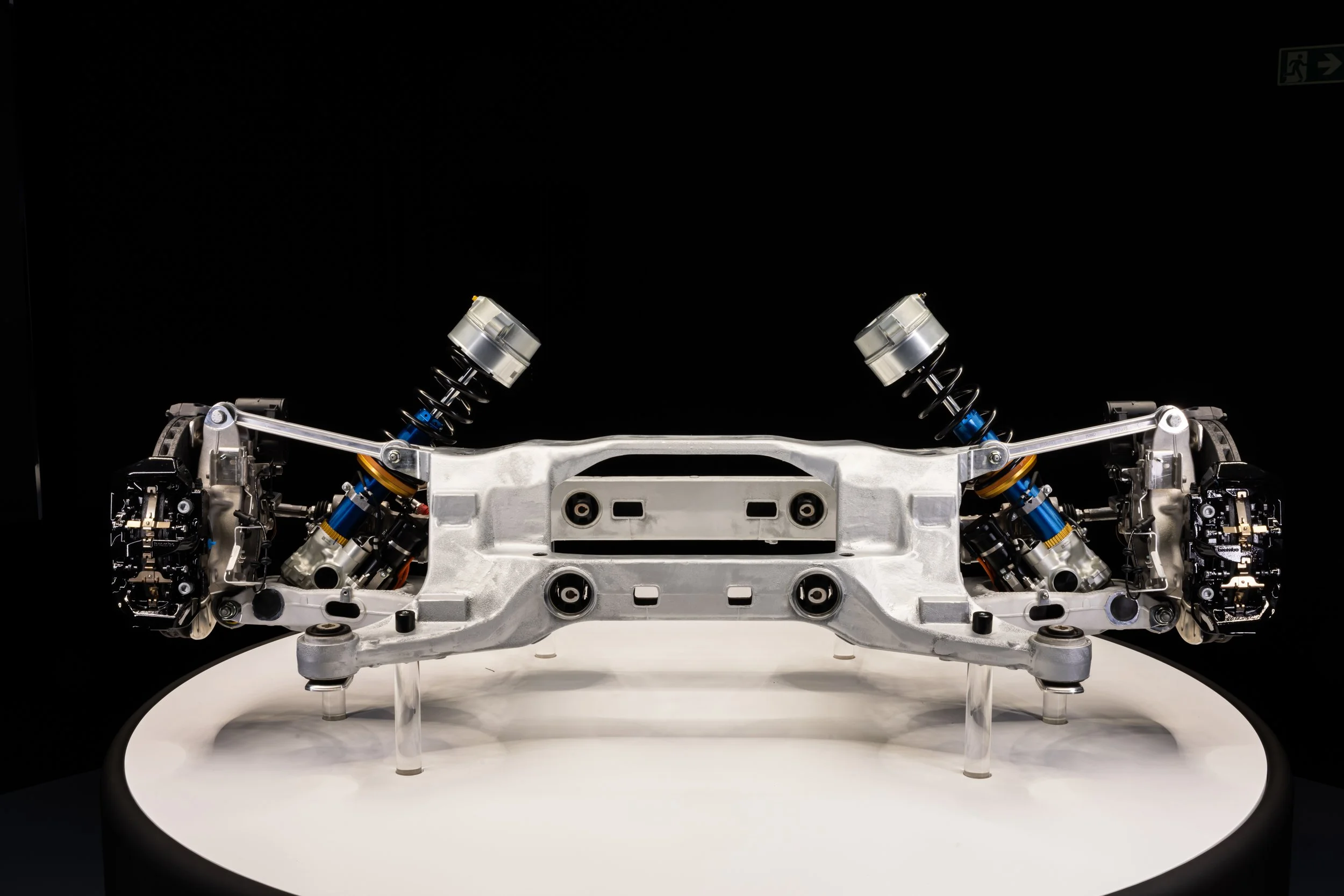

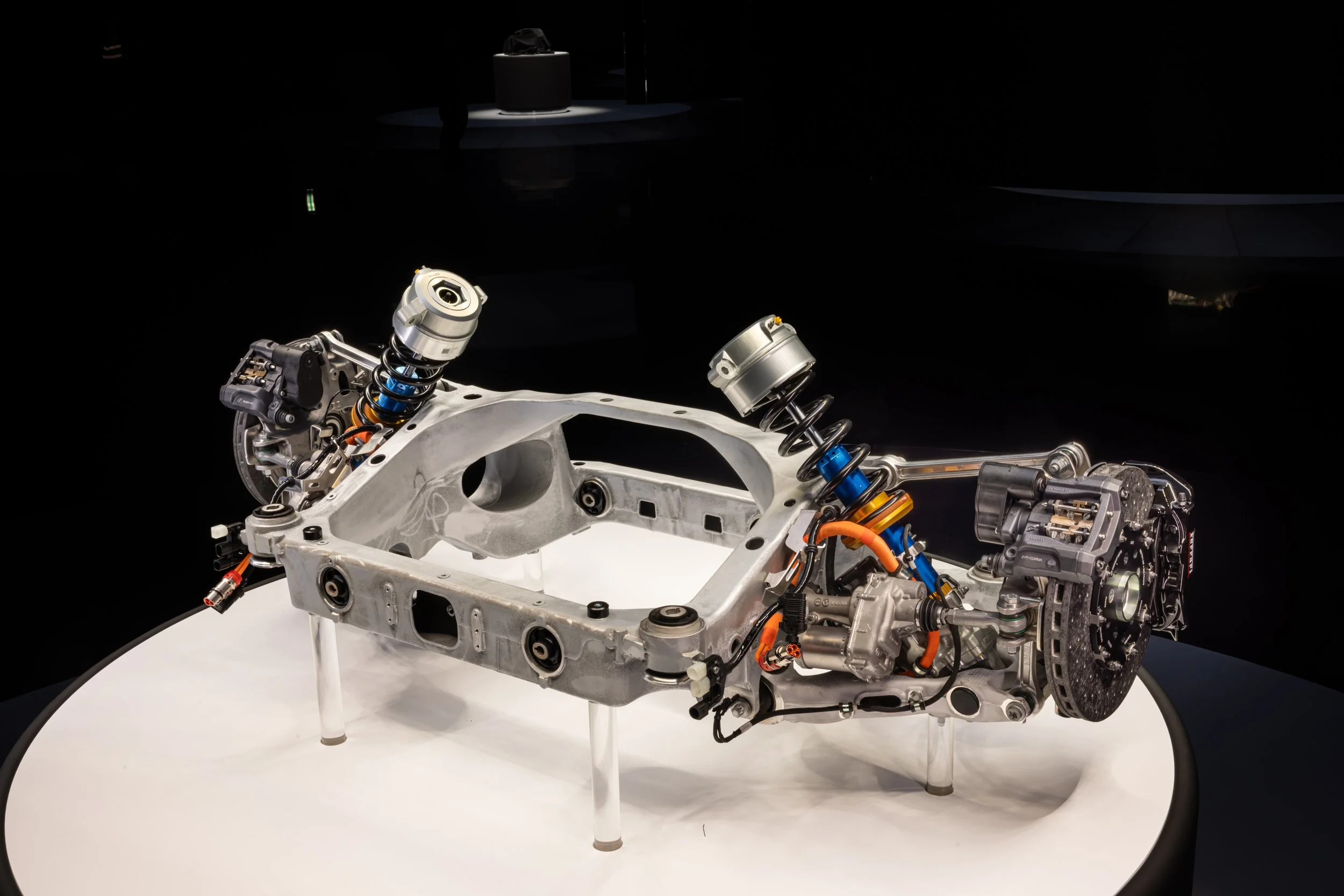

Ferrari debuts the first separate rear subframe in its history to reduce cabin noise and vibration while preserving the stiffness and dynamic precision expected of a car from Maranello. The third-generation 48V active suspension system, introduced on the Purosangue and further developed for the F80, enhances ride comfort, body control, and vehicle dynamics by distributing cornering forces optimally across all four wheels.

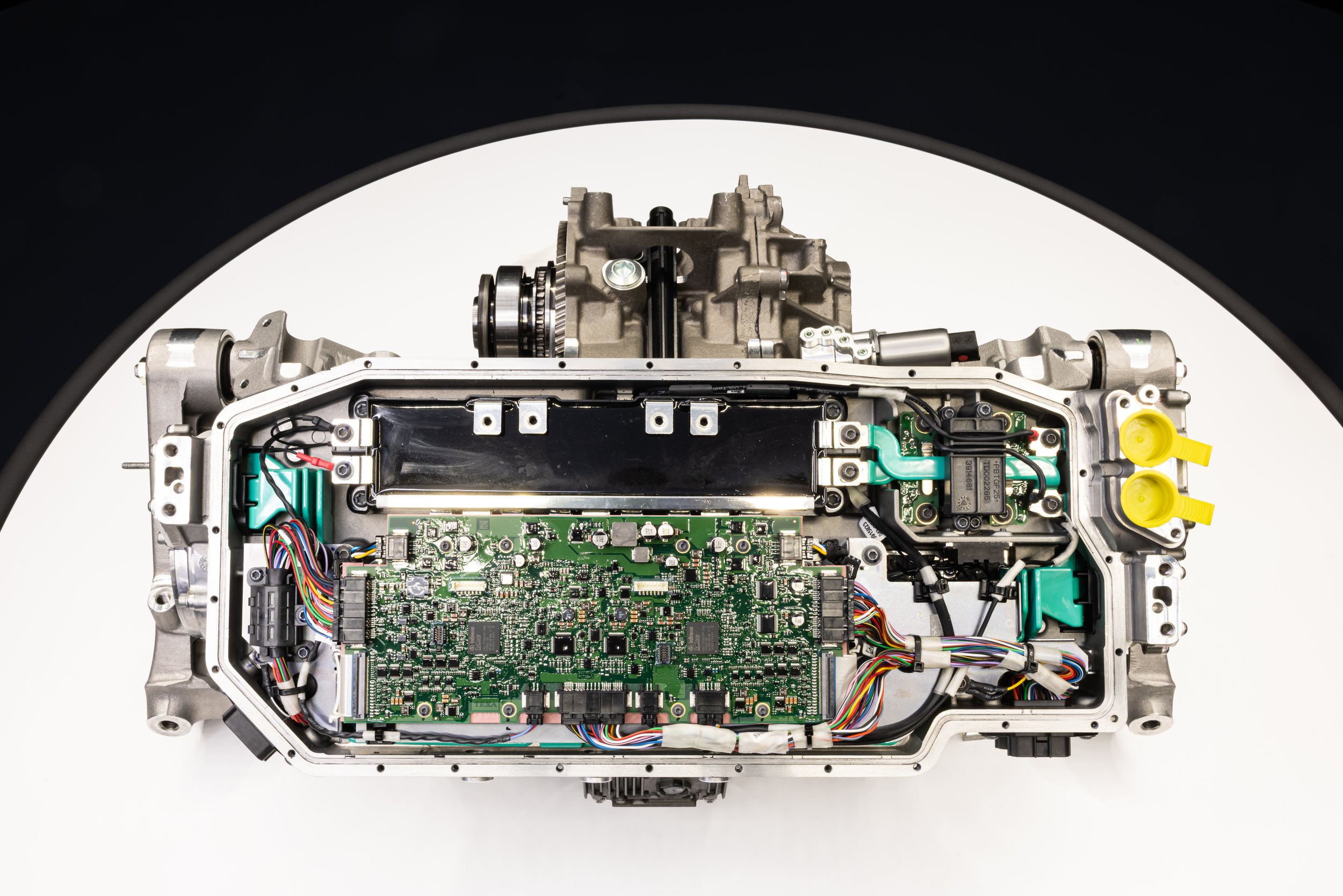

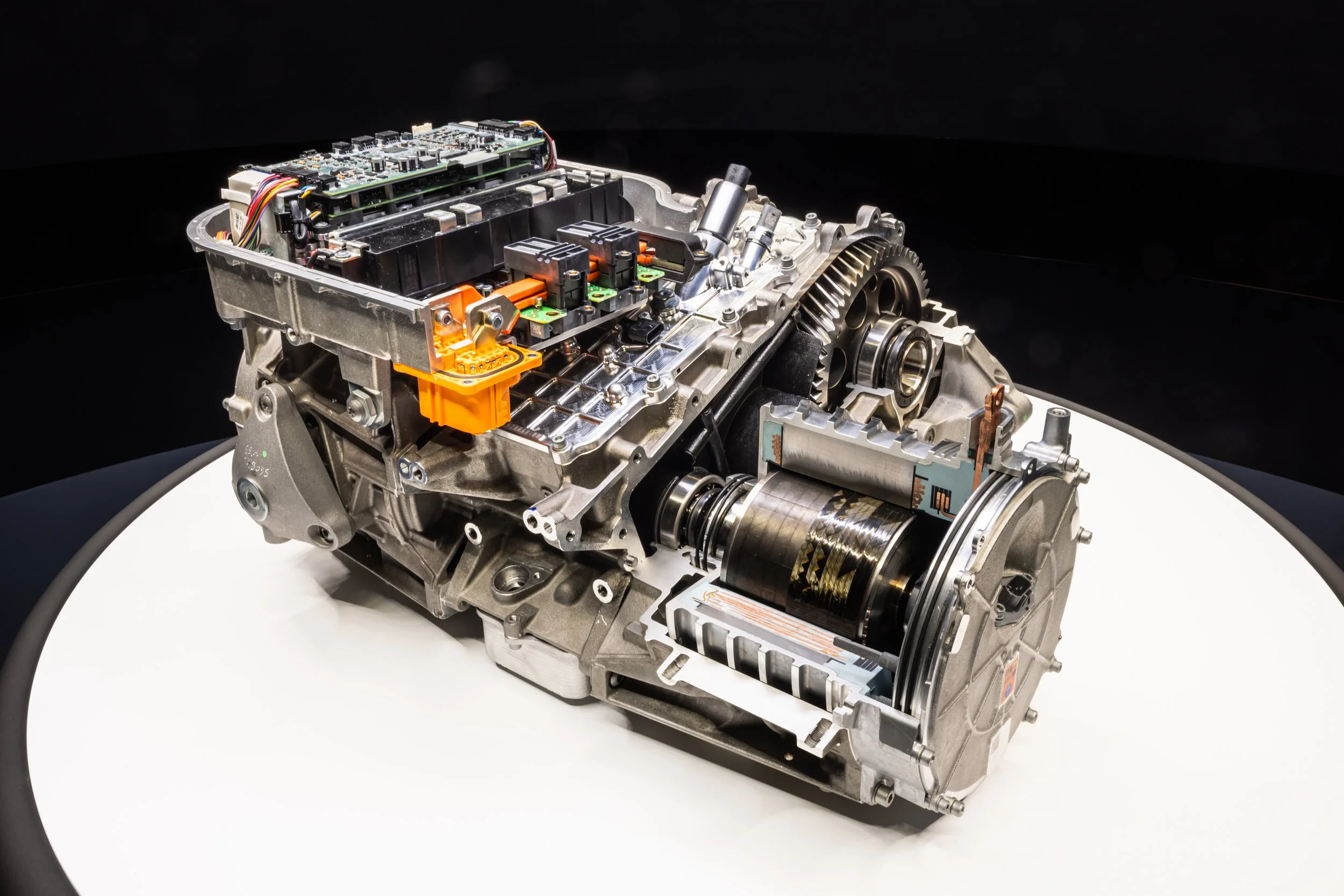

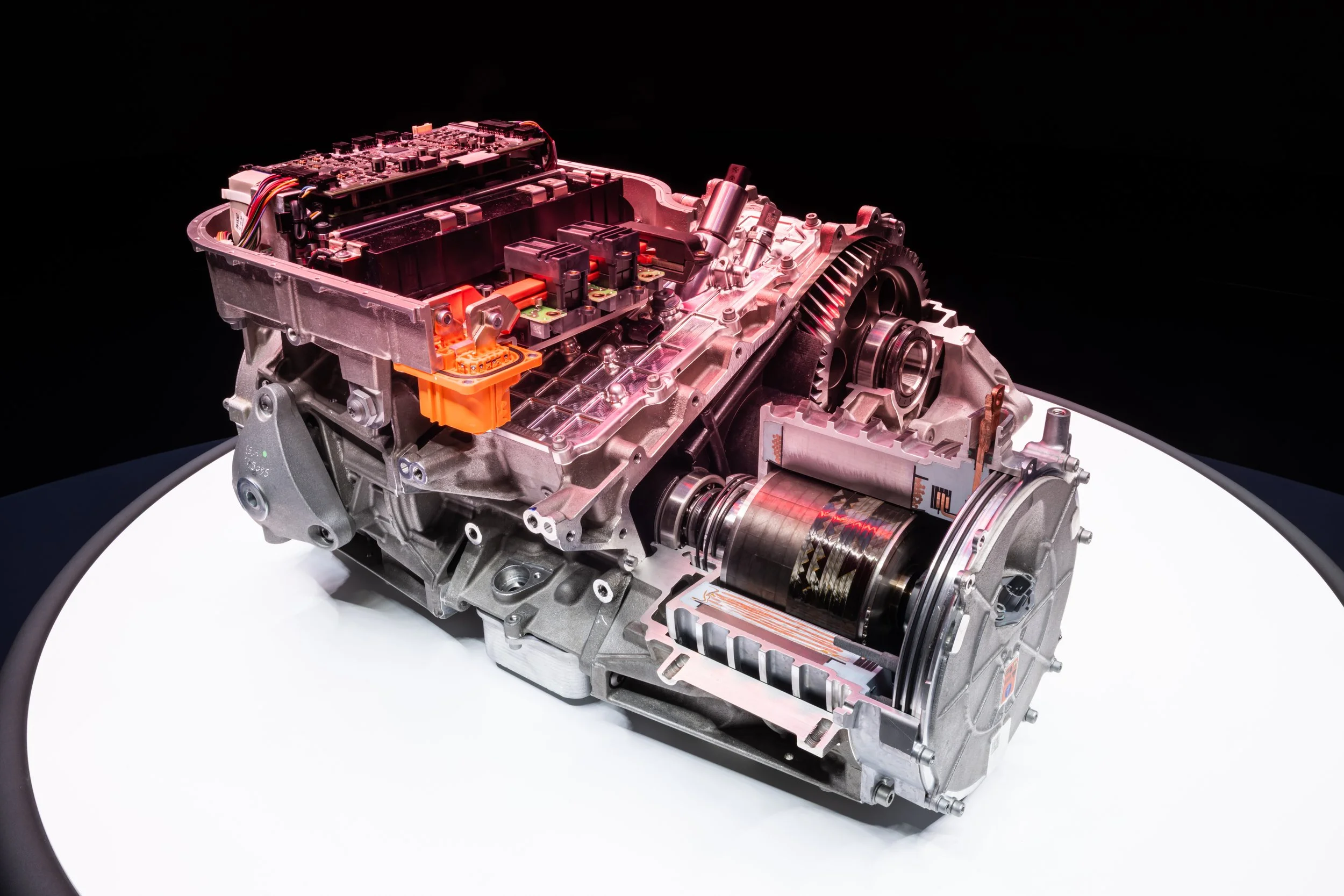

Ferrari designed and built two electric axles entirely in-house, each carrying a pair of permanent-magnet synchronous motors with Halbach-array rotors, industrialised from F1 technology. The front axle achieves a power density of 3.23 kW/kg and a peak efficiency of 93%. The rear axle reaches 4.8 kW/kg with the same peak efficiency. The fully integrated front inverter delivers up to 300 kW and weighs just 9 kg, a benchmark for compact power electronics in a luxury EV.

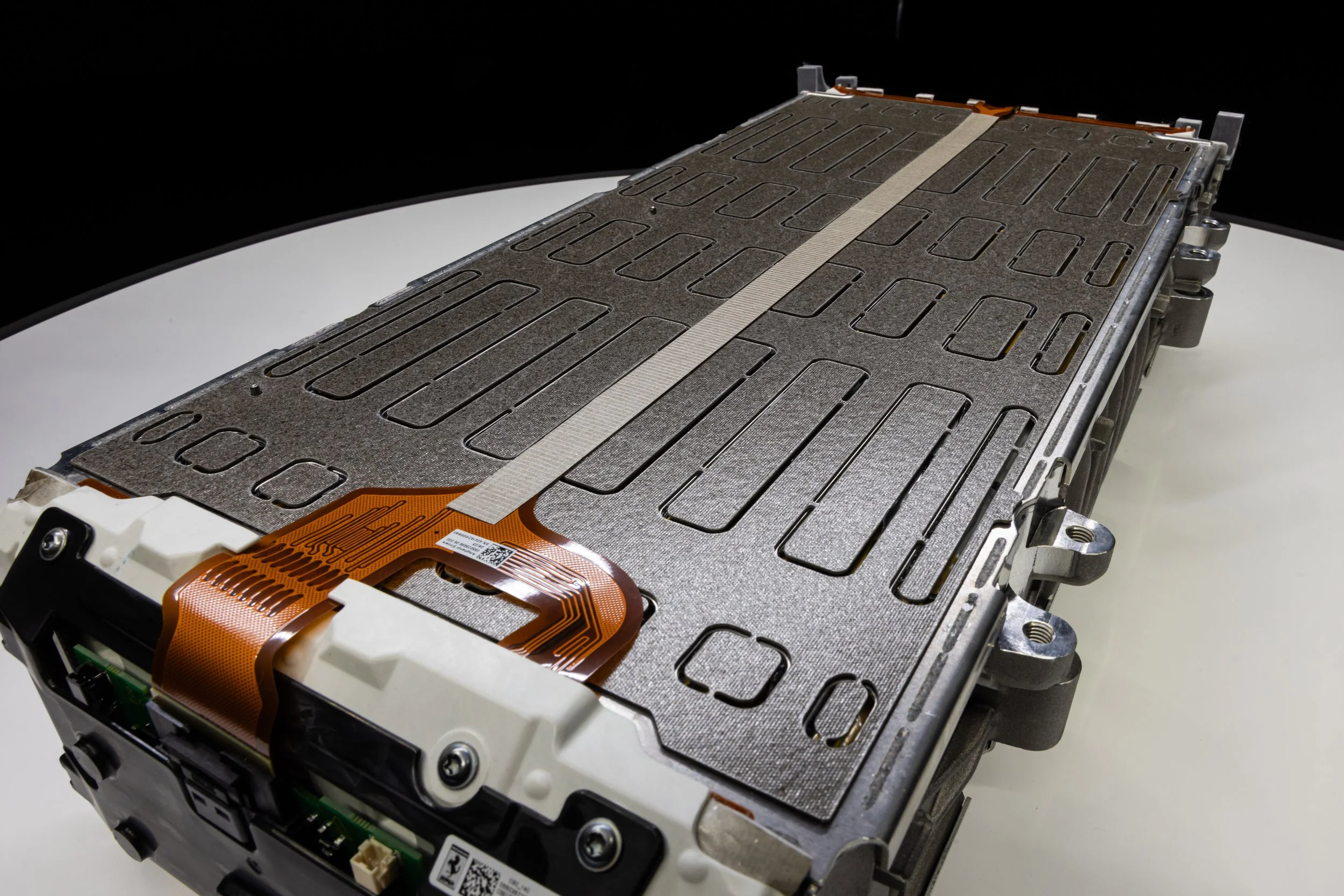

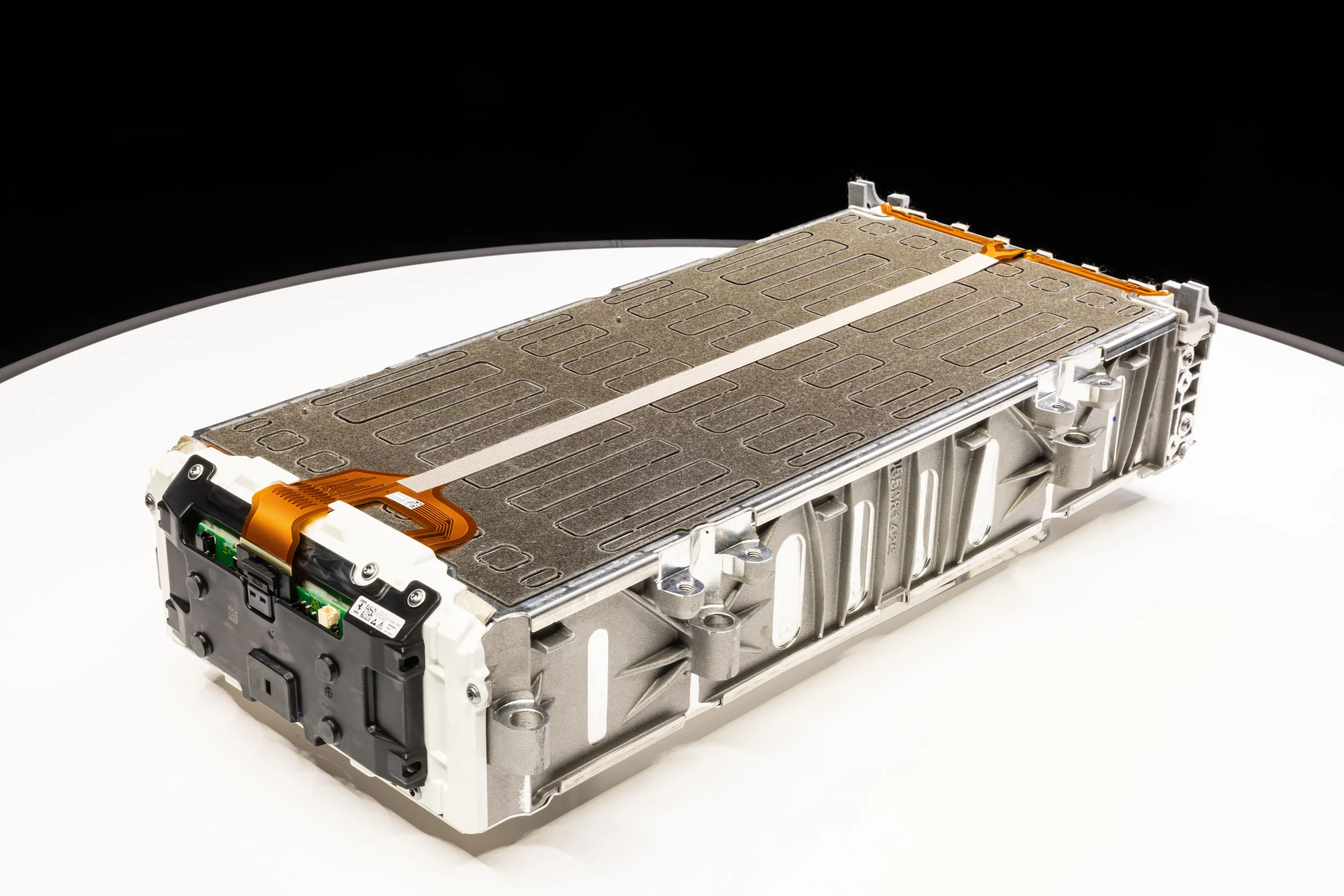

Maranello also designs and assembles the battery. It offers an energy density of almost 195 Wh/kg—the highest of any electric car—and a cooling system that optimises heat distribution for repeatable performance. Three driving modes — Range, Tour, and Performance — manage energy, power, and traction to optimise performance. The paddles behind the steering wheel offer five progressively higher levels of torque and power delivery, resulting in a seamless surge of acceleration and a more engaging drive.

The Vehicle Control Unit updates dynamic parameters 200 times per second to anticipate and coordinate suspension, traction and steering. This predictive control ensures agility, stability and precision at all speeds, enhancing the driver-centric feel of this electric Ferrari.

Ferrari has also engineered a distinctive sound to suit the electric powertrain. A high-precision sensor captures mechanical vibrations from the powertrain. It amplifies them to deliver an authentic aural signature that mirrors the car’s dynamic behaviour and provides direct feedback to the driver when it matters most.

The unveiling is set to continue in early 2026 with a preview of interior design concepts. Ferrari will then host the World Premiere in spring next year, where it will present the final harmony of technology and design.

The Elettrica’s chassis features an extremely short wheelbase, inspired by mid- and rear-engined berlinettas. Positioning the driver close to the front wheel heightens dynamic feedback while maintaining accessibility and comfort similar to those of GT models. Ferrari solved the crash-energy challenges of a heavier EV by using the front shock towers as energy absorbers and by locating the front electric motors and inverter to dissipate loads before they reach the chassis nodes, thereby enhancing safety and protecting structural integrity.

Engineers integrated the battery into the chassis under the floor to minimise total system weight and lower the centre of gravity. The chassis itself protects the pack, with spaces between modules and sills designed to absorb energy in the event of a side impact. Cells are positioned at the centre of the modules to facilitate absorption, and the lower cooling plate shields against intrusion from below. Ferrari’s patented assembly process further increases structural stiffness.

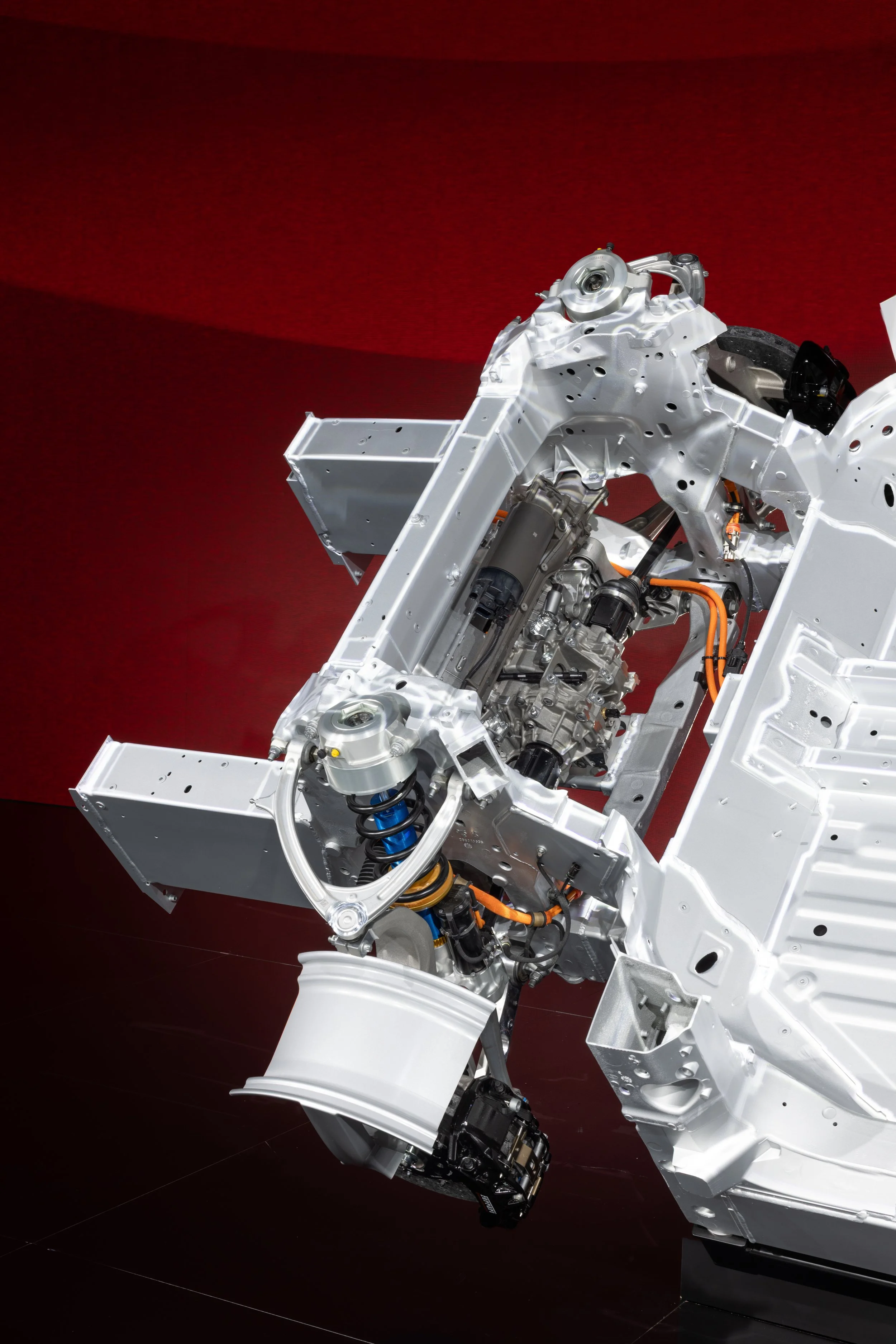

Ferrari targeted the rear axle to reduce rolling noise and powertrain vibration, while maintaining its signature handling and avoiding weight penalties. The answer was an elasticised mechanical subframe that spaces elastomeric bushes widely. This provides the stiffness of a rigid subframe under lateral loads while allowing the necessary compliance for ride comfort. Specific bushes filter tyre noise and axle vibration, combining high lateral stiffness with vertical and longitudinal flexibility to isolate road inputs without sacrificing precision.

To keep weight down despite the subframe’s size, Ferrari adapted its hollow casting technology from the chassis to create the largest one-piece hollow casting it has produced. The design maintains service access, and the connection system allows for independent maintenance of the rear axle, suspension, and battery, all encapsulated within a single, integrated load-bearing structure. Engineers mounted the active suspension inverters directly in the subframe, so their mass helps isolate vibration without the need for extra passive components. The result adds only a few kilos over a rigid solution while delivering quieter operation and undiminished driving pleasure.

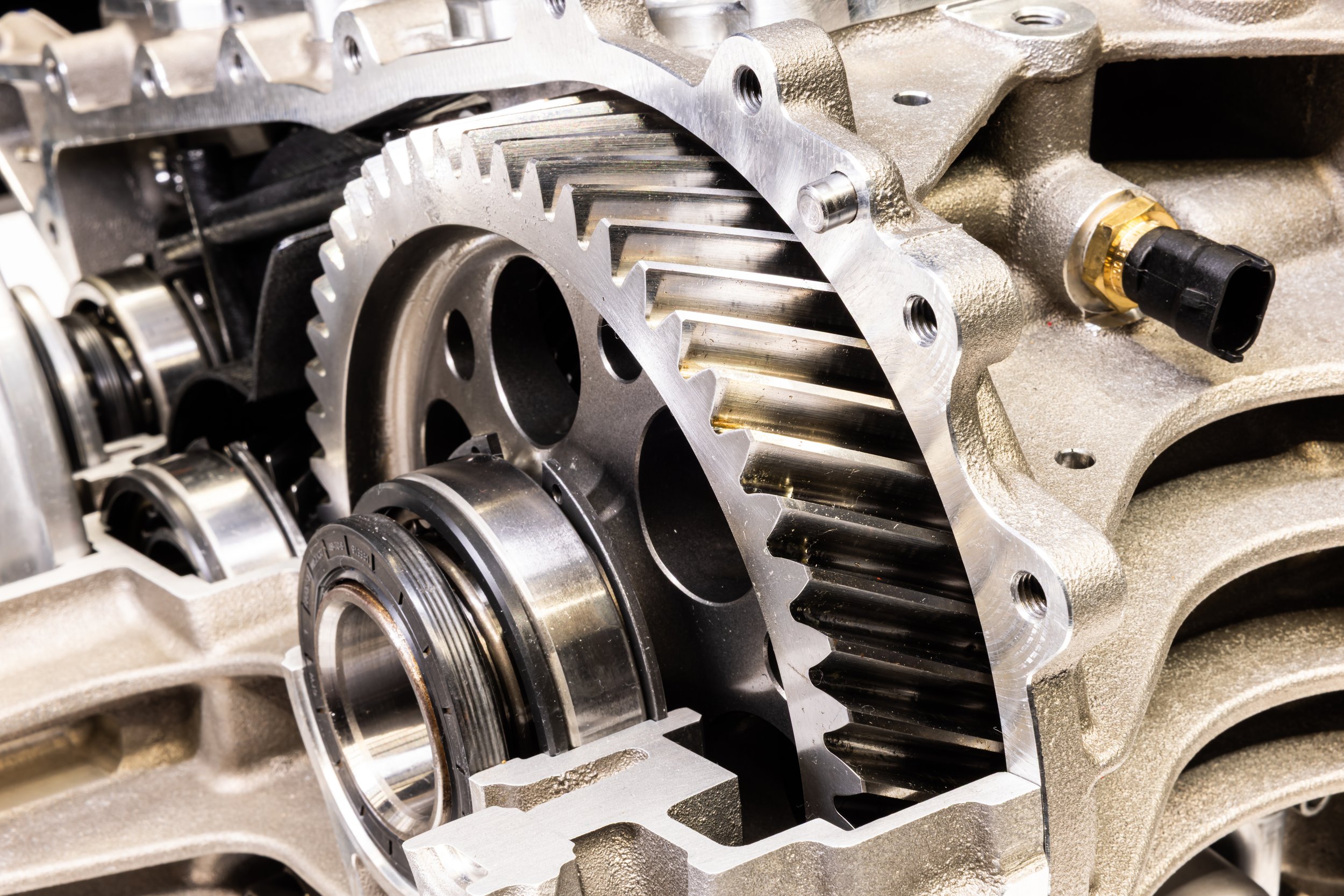

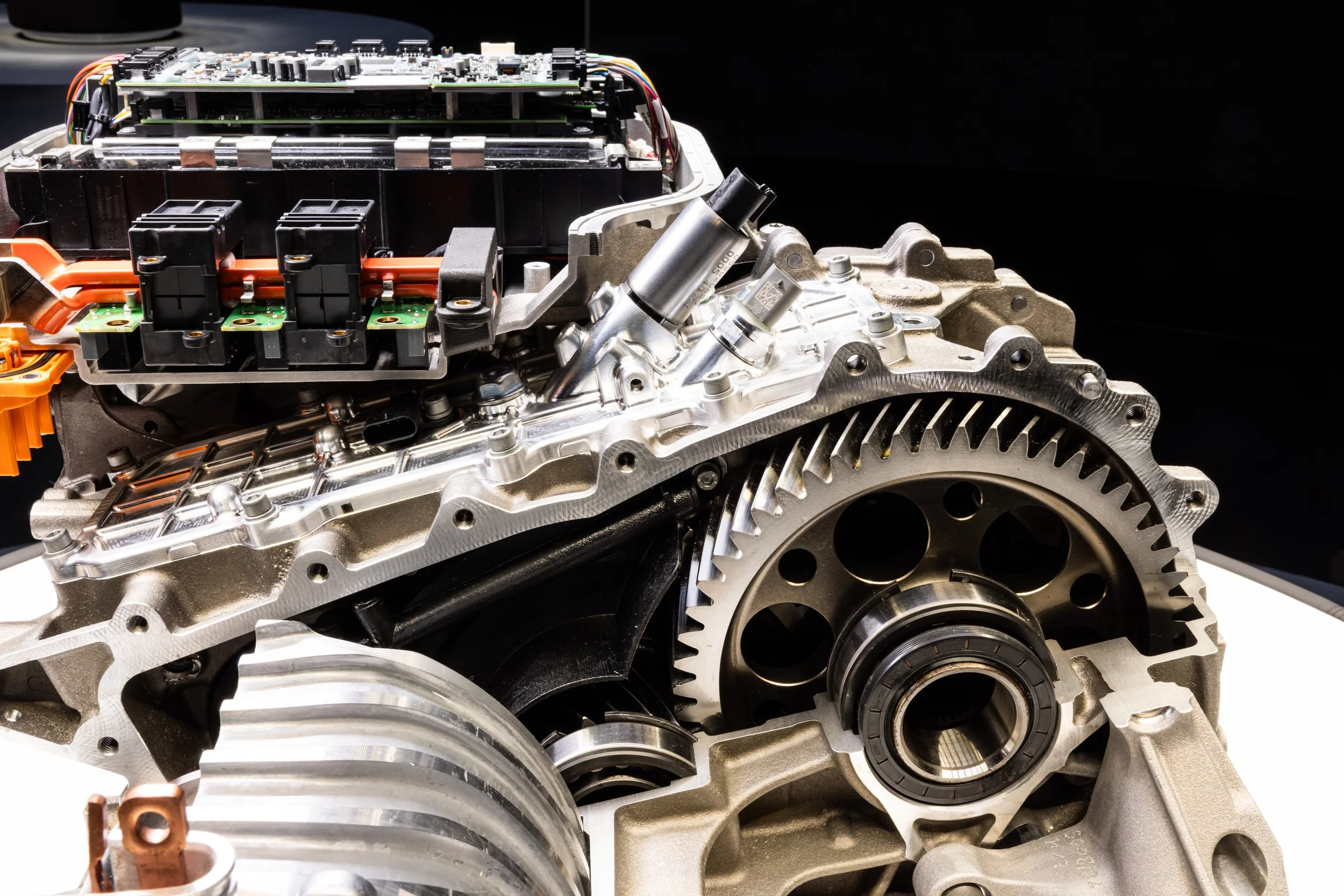

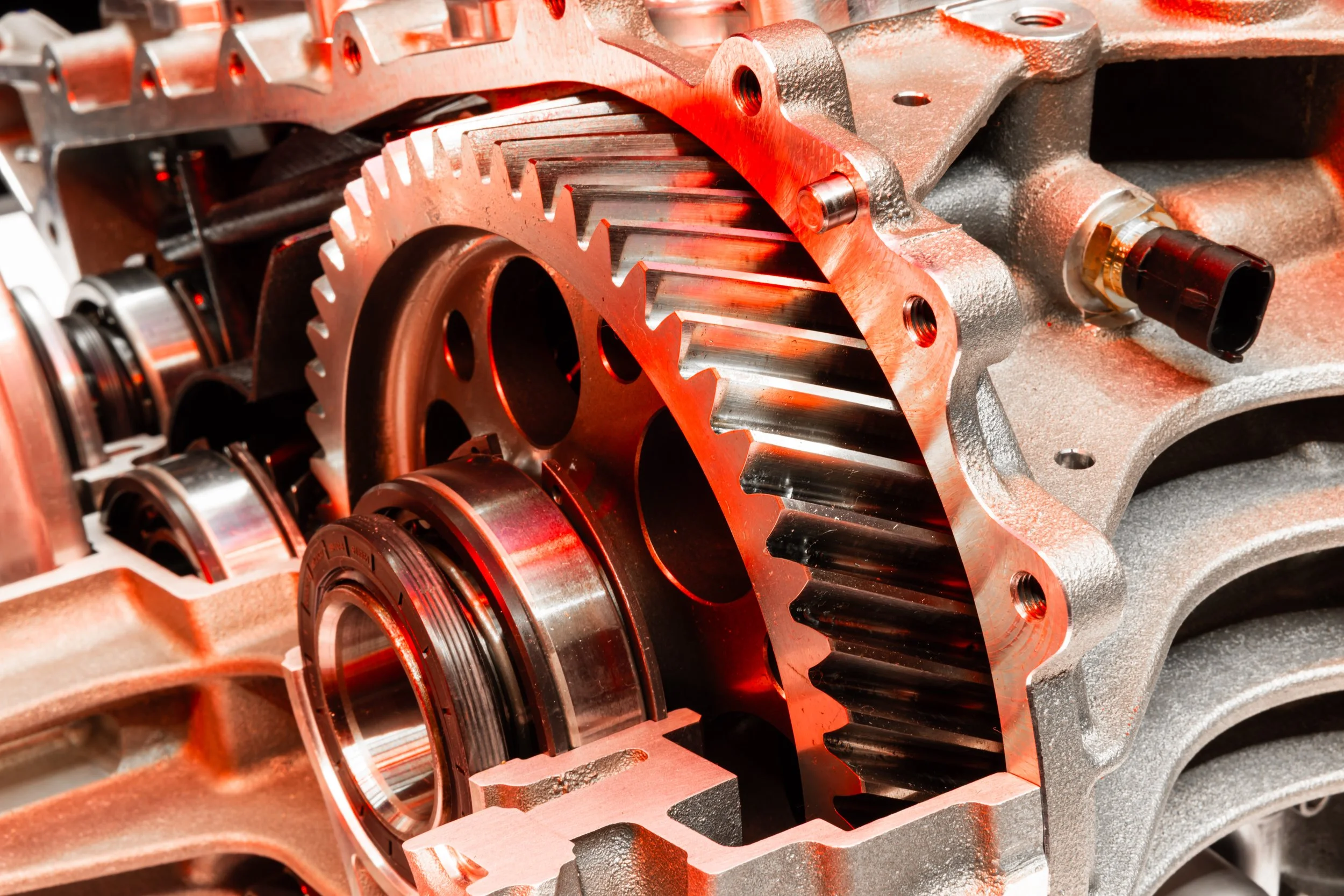

Both axles use two independent electric motors to enable precise torque vectoring and improve the car’s dynamic behaviour. Ferrari developed its transmission, inverters, and motors in-house for total control, class-leading power density, high electrical efficiency, and low NVH. Casting components in the company’s foundry ensures build quality and tight process control. All castings utilise a secondary aluminium alloy, which can reduce CO₂ emissions by up to 90% compared to conventional alloys, with no loss of mechanical performance.

The front axle delivers 210 kW and can decouple at any speed, up to top speed, to switch the car to rear-wheel drive and improve efficiency when four-wheel drive is unnecessary. At full acceleration, it can deliver up to 3500 Nm to the wheels. Its highly integrated layout places power electronics on the axle to shrink dimensions and boost efficiency. The rear axle provides up to 620 kW and can transmit 8000 Nm to the road in Performance Launch mode, reinforcing the Elettrica’s status as an electric supercar.

Ferrari equips the front axle with a disconnect system that fully decouples the motors from the wheels, balancing efficiency and energy use. In the eManettino position, set for motorway driving, the car operates in pure rear-wheel drive. When conditions demand, the system engages the front motors for all-wheel drive. In the other two eManettino positions, the vehicle remains all-wheel drive. Advanced gear synchronising technology cuts system weight by 70% compared with the previous generation and engages or disengages in 500 milliseconds, blending efficiency with driving pleasure.

An optimised lubrication circuit supplies exactly the oil needed to the gears and mechanisms for maximum efficiency. A dry sump pump and a heat exchanger are integrated into the axle. A main valve governs lubrication pressure for the actuators, while two additional valves control the disconnect function and the rear axle park lock. This architecture reduces complexity and lowers weight.

Ferrari pushed permanent magnet synchronous motor technology to its limits. High rotational speeds — 25,500 rpm at the rear and 30,000 rpm at the front — deliver peak power of 310 kW and 105 kW, respectively, in compact packages that enable a space-efficient axle design. Surface-mounted, segmented magnets arranged in a Halbach array direct magnetic flux to the stator to maximise torque density and reduce mass. The stator utilises ultra-thin 0.2 mm non-oriented silicon-iron laminations, stacked through a self-bonding process to minimise short-circuit risk. Concentrated windings minimise end height, with tooth connections soldered to a compact terminal block. Litz wire minimises skin and proximity losses, enabling sustained performance at very high frequencies with large phase currents.

Ferrari vacuum-impregnates the stator with a high-thermal-conductivity resin that conducts heat 40 times more effectively than air, while also mechanically strengthening the stator. With a maximum angular acceleration of 45,000 rpm per second, the front motors spin from standstill to maximum speed in under one second for instant response. Engineers industrialised prototype-grade processes, press-fitting 1.6 mm carbon sleeves into the rotor to contain magnets just 0.5 mm from the stator. At 30,000 rpm, a 93-gram magnet generates a centrifugal force of 390 bar, yet the sleeve maintains integrity with negligible impact on mass or air gap. This compact, high-performance motor also powers the F80 supercar's front axle.

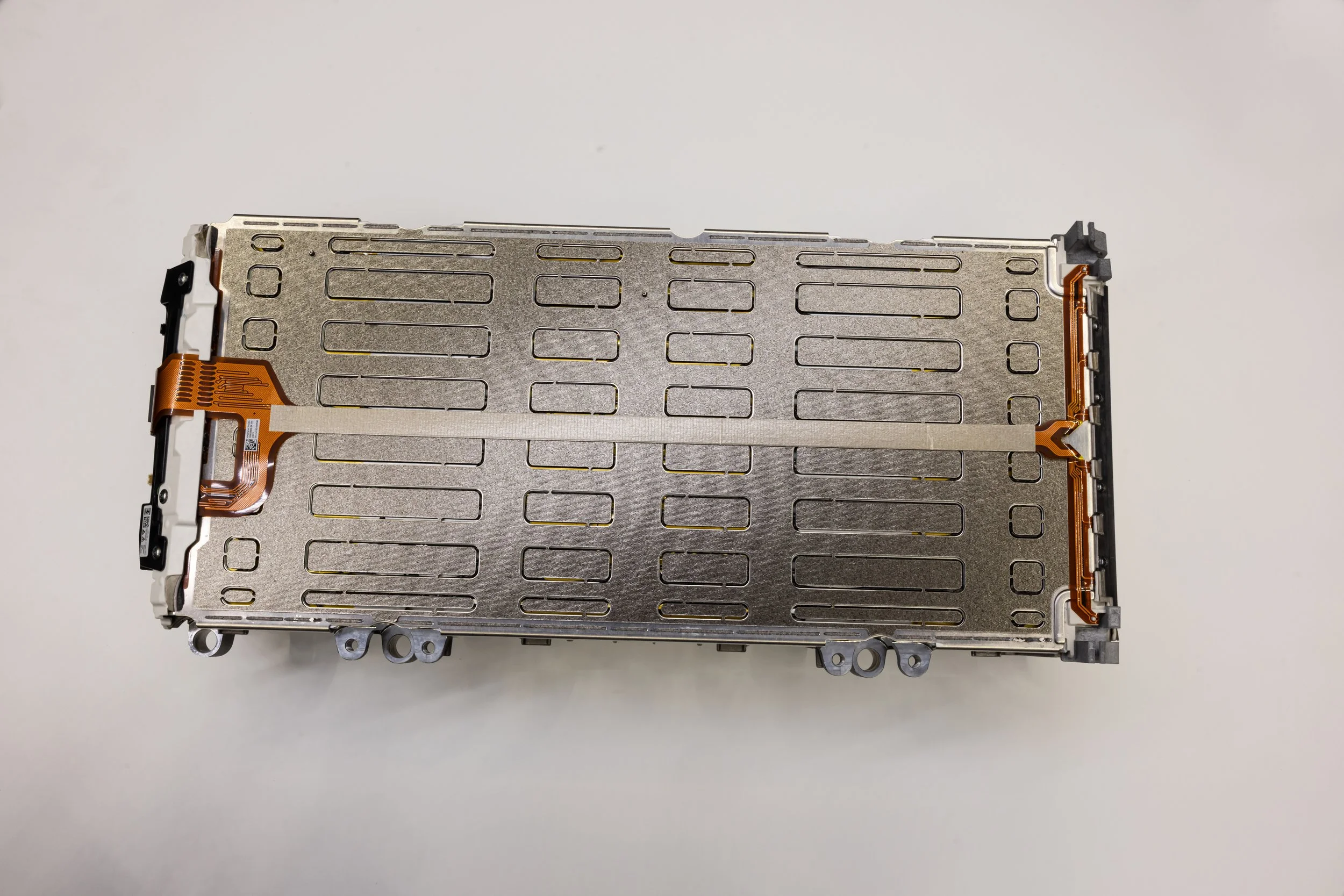

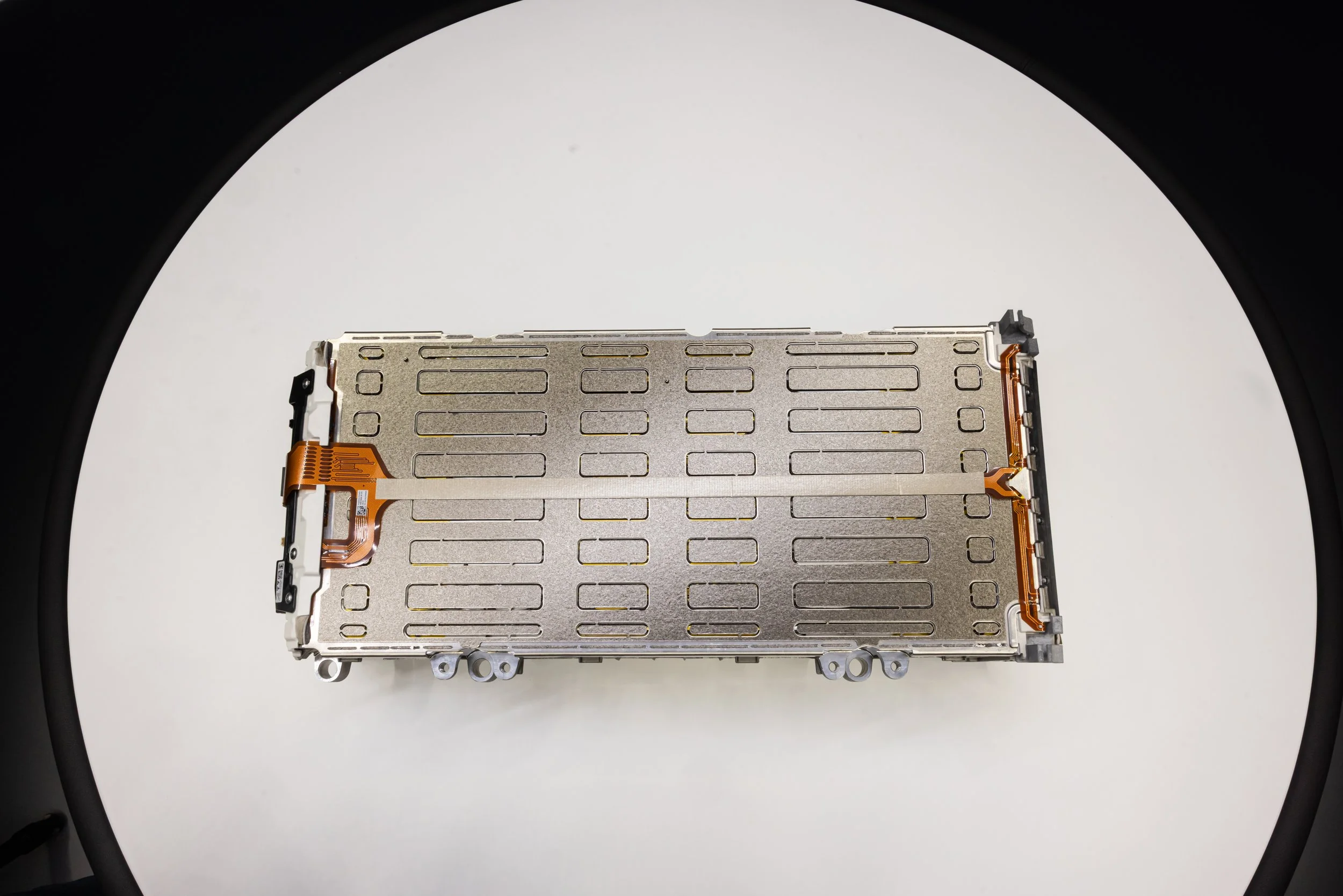

Ferrari designs and assembles the 122 kWh battery in-house, integrating it into the floor, which lowers the centre of gravity by 80 mm compared to an ICE equivalent. Engineers used an optimisation approach to reduce the weight and increase the stiffness of the battery and chassis as a system. They placed cells to minimise inertia and centre of gravity, locating mass behind the driver where possible. Approximately 85% of the module's weight is located under the floor, with the remaining 15% situated under the rear seat. This package shortens the wheelbase and minimises inertia while achieving a 47% front and 53% rear distribution for balanced dynamics.

The front seat layout accommodates cells without reducing rear space. Moving the driver’s seat forward allowed for a more reclined rear seating position, providing improved comfort. Ferrari shifted parts of the protection role from the battery to the body, placing cells far from likely impact zones. The gap between the cell and the sill acts as a crumple zone and houses cooling lines. Front and rear modules concentrate cells centrally, with the surrounding areas absorbing energy and reducing inertia. Suspending cells from the floor creates an energy-absorbing gap, allowing for a lighter protective shield. A fragile aluminium shell integrates cooling plates that help keep the centre of gravity low and absorb impact energy without compromising safety.

Die-cast cell compression plates provide transverse strength and include the fastener points that fix the battery to the chassis. The battery becomes a structural element, pared back to two shells, and once secured with 20 central anchor points, the lower shell contributes to bodyshell stiffness. This approach delivers an energy density of almost 195 Wh/kg and a power density of about 1.3 kW/kg, figures that set the class benchmark. Ferrari developed the system for serviceability, allowing for the removal and replacement of modules or electronics without compromising structural parts or finishes.

The cooling system uses internal pipes and three plates: two attached to the housing and a smaller one that cools the upper modules. Delivery and return flows run through the same plate to equalise temperatures and prolong cell life. The battery cooling integrates fully with the primary vehicle circuit, managing flows from the front to the rear. A 15-module layout with six dual rows, one single row, and two upper modules utilises space efficiently without extending the wheelbase, thereby improving agility. Each module houses 14 resistance-welded cells with insulating and conductive partitions, while thermal paste between modules and plates optimises heat transfer. The cells exceed 305 Wh/kg and deliver 159 Ah, developed specifically to meet Elettrica’s performance targets.

Each module integrates a flexible printed circuit board (flex PCB) and a control unit that communicates with the Battery Management System in the E-Box. Ferrari developed both hardware and algorithms in-house. The E-Box also contains fuses, relays and sensors, and manages power and communication on the CAN line. The nominal voltage is approximately 800 V across 210 series cells, with a peak current of up to 1200 A and an RMS current of up to 550 A. A primary fuse can cut current above 2000 A in three milliseconds to protect against short circuits inside or outside the pack. Internal connections and front- and rear-connectors provide power to both inverters and auxiliaries, eliminating the need for long external cables. Central busbars handle very tight packaging safely and reliably, reflecting a philosophy of uncompromising efficiency, lightness and performance. The battery remains removable and repairable via a dedicated carrier.

The inverters convert high-voltage DC to AC for the motors and recover energy during braking. Ferrari integrates the front inverter into the axle to save space and weight. It controls both front motors, delivering up to 300 kW while weighing just 9 kg. At its heart, the Ferrari Power Pack combines six silicon-carbide modules, gate driver boards and integrated cooling in a compact package. The driver board manages MOSFET behaviour and, with an 800 V to 48 V DC/DC converter, enables precise torque distribution. The switching frequency varies from 10 to 42 kHz to balance efficiency, acoustic comfort, heat management, and motor response. Ferrari employs a toggling strategy on the rear axle, periodically switching the inverter between on and standby states, thereby maintaining a constant mean torque by modulating at approximately 100 Hz. This yields about 10 km more range in motorway conditions without reducing performance. Order Noise Cancellation, combining Sound Injection and a Resonant Controller, monitors and cancels unwanted current harmonics to reduce whine and losses while preserving response.

Rather than imitating the timbre of an internal combustion engine, Ferrari highlights the character of the electric drivetrain. A rear-axle accelerometer senses powertrain frequencies that an amplifier projects externally, much like an electric guitar. The system stays quiet in normal driving to maximise comfort, then activates under acceleration or when the driver uses the paddles to deliver functional feedback and enhance connection.

The lower centre of gravity created by the electric layout enabled a significant evolution of Ferrari’s active suspension from the Purosangue and F80. Lower active forces are needed to control roll and pitch, which improves both precision and vertical comfort. A new recirculating ball screw with a 20% longer pitch reduces inertial forces transmitted to the chassis. The electric motor generates the same torque as before but actively manages forces between the chassis, tyre, and road without compromising ride compliance for body control. New shock absorbers shed 2 kg and feature a thermocouple to monitor oil temperature, ensuring consistent behaviour in all conditions. Ferrari removes the suspension override from the Manettino to separate comfort settings from other controls. With four independently controlled wheel modules, four motors and four-wheel steering, the Elettrica can manage vertical, longitudinal and lateral forces in all conditions to deliver the thrills expected of a car bearing the Prancing Horse badge.

Torque Shift Engagement underpins the sensation of relentless acceleration. Five selectable levels, selected sequentially with the right paddle, progressively increase power and torque across a wide speed range. Instant motor response smooths transitions so any torque dip becomes almost imperceptible, giving the driver time to savour the surge. When braking, the left paddle increases the intensity of simulated engine braking for a more exciting feel.

Two steering-wheel controllers tailor the experience. The right-hand Manettino sets vehicle dynamics: from Ice, which maximises stability and keeps all-wheel drive even with very low grip, to ESC-Off, which leaves only the essentials active —active suspension and front torque vectoring —freeing the rear axle for pure driving pleasure—new Dry mode debuts for daily driving between Wet and Sport. The left-hand eManettino controls energy architecture, dictating power-on-tap-driven axles and peak performance, with three configurations to suit different styles.

Tyre development pursued a bold brief, cutting rolling resistance by 15% without harming grip or safety in dry or wet conditions. The car’s lower centre of gravity and inertia reduce load transfer, easing tyre strain and opening new construction solutions. Ferrari and its suppliers offer five dedicated tyres: three for dry use, one for winter, and one run-flat, which broadens versatility without blunting performance.

Performance and technical specifications confirm the Elettrica’s place among the world's top electric supercars. It sprints from 0 to 100 km/h in 2.5 seconds and reaches a top speed of 310 km/h. Boost mode delivers more than 1000 CV. WLTP range exceeds 530 km. The wheelbase measures 2960 mm. The kerb weight is approximately 2,300 kg, with a 47% front and 53% rear weight distribution. The front e-axle supplies 210 kW and up to 3,500 Nm at the wheels, with 140 Nm at the motor in Performance Launch mode, a 3.23 kW/kg density at 93% efficiency, a 30,000 rpm capability, more than 300 kW inverter power, and a 65 kg mass. The rear e-axle delivers 620 kW and up to 8,000 Nm at the wheels, with 355 Nm at the motor in Performance Launch. It achieves 4.80 kW/kg at 93% efficiency, 25,500 rpm, and utilises more than 600 kW of inverter power, weighing 129 kilograms. The battery comprises 210 cells, organised into 15 modules of 14 cells, with a total energy density of 195 Wh/kg, a cell density of 305 Wh/kg, a gross capacity of 122 kWh, a maximum voltage of 880 V, and a maximum recharge power of 350 kW. Together, these figures showcase a Ferrari electric car engineered to set new standards in performance, control and emotional connection.